this is what happens when eight different exponential technologies all explode onto the scene at once.

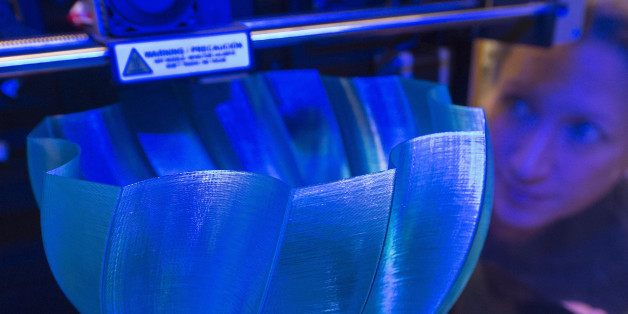

This blog (the 5th of 7) is a look at 3D printing. Future blogs will look at other tech areas.

An expert might be reasonably good at predicting the growth of a single exponential technology (e.g. 3D Printing), but try to predict the future when A.I., Robotics, VR, Drones, and Computation are all doubling, morphing and recombining… You have a very exciting (read: unpredictable) future. This year at my Abundance 360 Summit I decided to explore this concept in sessions I called “Convergence Catalyzers.”

For each technology, I brought in an industry expert to identify their Top 5 Recent Breakthroughs (2012-2015) and their Top 5 Anticipated Breakthroughs (2016-2018). Then, we explored the patterns that emerged.

At A360 this year, my expert on 3D Printing was Avi Reichental.

Avi is the Founder and CEO of XponentialWorks, an expert advisory, venture investment and incubation ecosystem company that is focused on monetizing exponential tech innovation and business model disruption. For 12 years, Avi was the CEO of 3D Systems, the largest publicly traded 3D printing Company in the world. A dear friend and brilliant entrepreneur, Avi is also part of our core faculty in additive manufacturing at Singularity University.

Before we dive in, here’s some more context around 3D printing:

3D printing, also known as additive manufacturing, is the process of printing, layer by layer, any three-dimensional object based on a digital file.

In a 3D printer, one or more print heads extrudes a small amount of materials in precise locations to build objects point by point from the bottom up.

Today we can 3D print in full color and in over 250 different materials ranging from titanium to rubber, plastic, glass, ceramic, leathers and even chocolate.

3D printers can create very complex structures of mixed materials and print almost anything, from jet engines to jewelry to houses and even medical prosthetics.

3D printing transforms the entire manufacturing process. Customization and complexity come for free and large-scale custom manufacturing is no problem.

Additive manufacturing also saves tremendous costs, requiring as little as 10% of the raw materials expended in traditional manufacturing and eliminating the need for inventory.

Ultimately, 3D printing dematerializes, demonetizes and democratizes manufacturing and turns us all into creators.

If you or your customers are in the business of making anything, 3D printing is on the road to disrupting your industry and your business.

[“Source-huffingtonpost”]

Techosta Where Tech Starts From

Techosta Where Tech Starts From