When your inspection department reaches its capacity or the production line introduces a new component that requires new measurement tools, you have to decide whether you want to expand your in-house quality control or use contract metrologists. On the one hand, bolstering your capabilities in-house can reduce transportation and wait times. Transporting pieces off-site takes time and means you have to rely on someone else’s schedule. However, outsourcing can protect you from making wasteful equipment purchases and meet short-term, temporary demands such as inspecting difficult and atypical components. Some of the reasons to consider contracting out your inspection requirements include savings on training, compensating for staffing shortages, filling complex programming needs, and solving glitches that are outside your ability to identify.

Training Costs

With every new coordinate measurement machine comes new software and more training demands. Employee education can be expensive, especially when you have to send staff off-site for several days of courses. E-courses have come a long way in reducing costs and helping cross-train operators, especially as they allow staff to stay in the factory. But the biggest obstacle to better and more diversely trained operators isn’t cost: it’s time. Too many shops can’t afford to have operators spend so much time away from the floor. Sometimes it makes more sense to send parts out-of-house than to lose all those hours.

Staff Shortages

Staff shortages go hand-in-hand with obstacles to education, but cross training isn’t always enough to solve the demand for coordinate measurement machine operators. Experts in multiple types of systems can be in demand in more than one place. When they’re called elsewhere, delays build up at equipment that’s in need but lacking an operator. Manpower shortages only get worse when sick leave and holidays come into play. Measurement solutions providers can make up the difference when you don’t have the staff to stay on top of inspection.

Glitches

When a part doesn’t fit, something’s gone wrong in the process, and you may not have the ability to discover where the fault lies. Bringing in outside measurement experts right away can reduce your delays and minimize the damage.

Programming

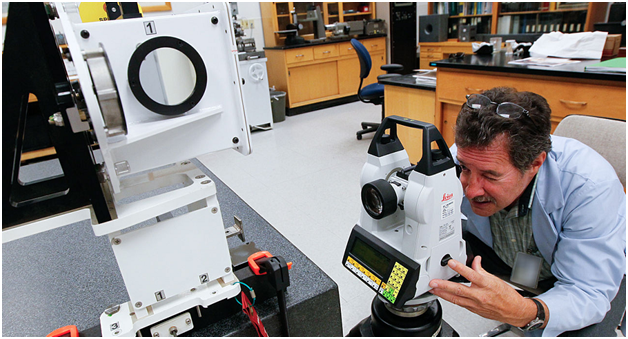

Outsourcing is ideal for complex programming for new parts. Contractors should offer a full range of software capacities for a wide variety of machines. For example, Canadian Measurements-Metrology, a North America-wide company with its headquarters in Mississauga, offers on and off-line programming for software running the gamut including Quindos, Spatial Analyzer, Polyworks, Modus, PC-DMIS, and more.

When it comes to new and short run components, outsourcing is often the fastest and most cost-effective method to follow. Instead of waiting for programs to be written, contract metrologists have fast solutions. Companies like CMM also keep every kind of coordinate measurement machine on hand and can handle any component, from microchips to supersized parts. Their tests and upkeep on in-house equipment far surpasses what most shops are capable of performing. With advancements in machines built for the shop floor, they can also come to your site and provide that extra capacity you need to fulfill a contract. For a full list of available contract services, stop by the CMM website today. Learn how outsourcing can benefit your bottom line.

Techosta Where Tech Starts From

Techosta Where Tech Starts From